Reliability Consulting

61% percent of manufacturing facilities follow the use of run-to-failure strategy which cost 3 times more than a predictive or proactive approach.

Our Methodology

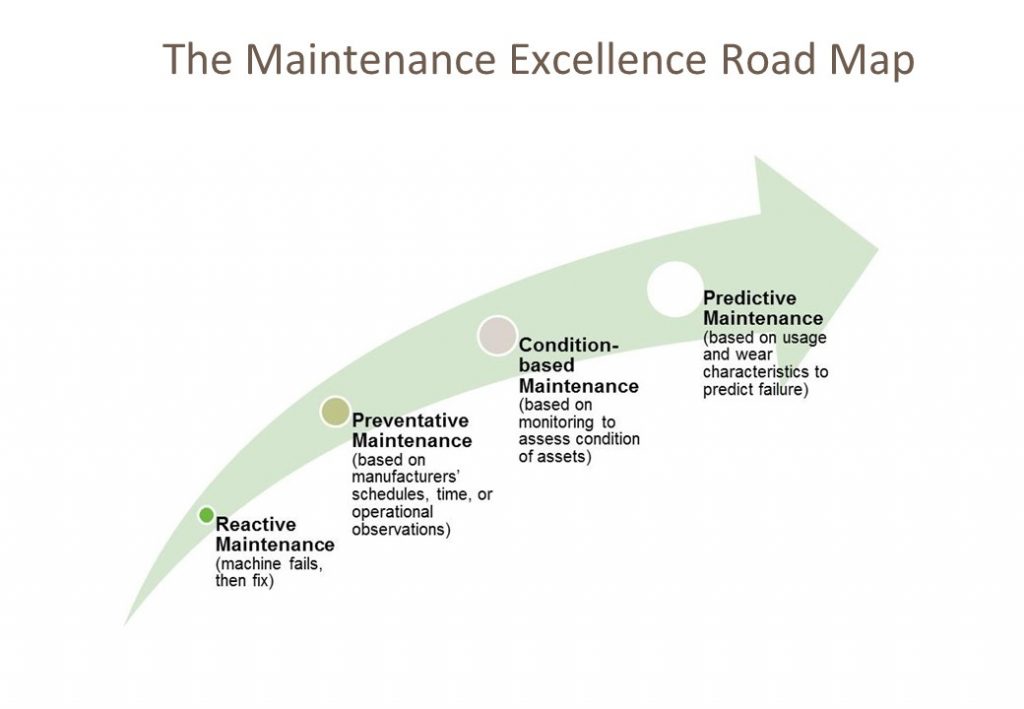

Our Reliability services are focused on two main drivers: Improving Reliability and Lowering Cost of Ownership for all key assets. We also focus on improving reliability through people by establishing a maintenance best practices culture transformation. Our processes include collaboration with all the organization’s departments to facilitate reliability improvements.

What we offer?

- Asset Criticality Ranking

- Failure Mode Effects Analysis (FMEA)

- Master Asset List

- MRO Optimization

- Planning and Scheduling

- Preventive Maintenance Optimization

- Predictive Maintenance Program

- Reliability-Based Maintenance

- Root Cause Analysis (RCA)

- Spare Parts Analysis

- Workflow Optimization

- Work Management Processes